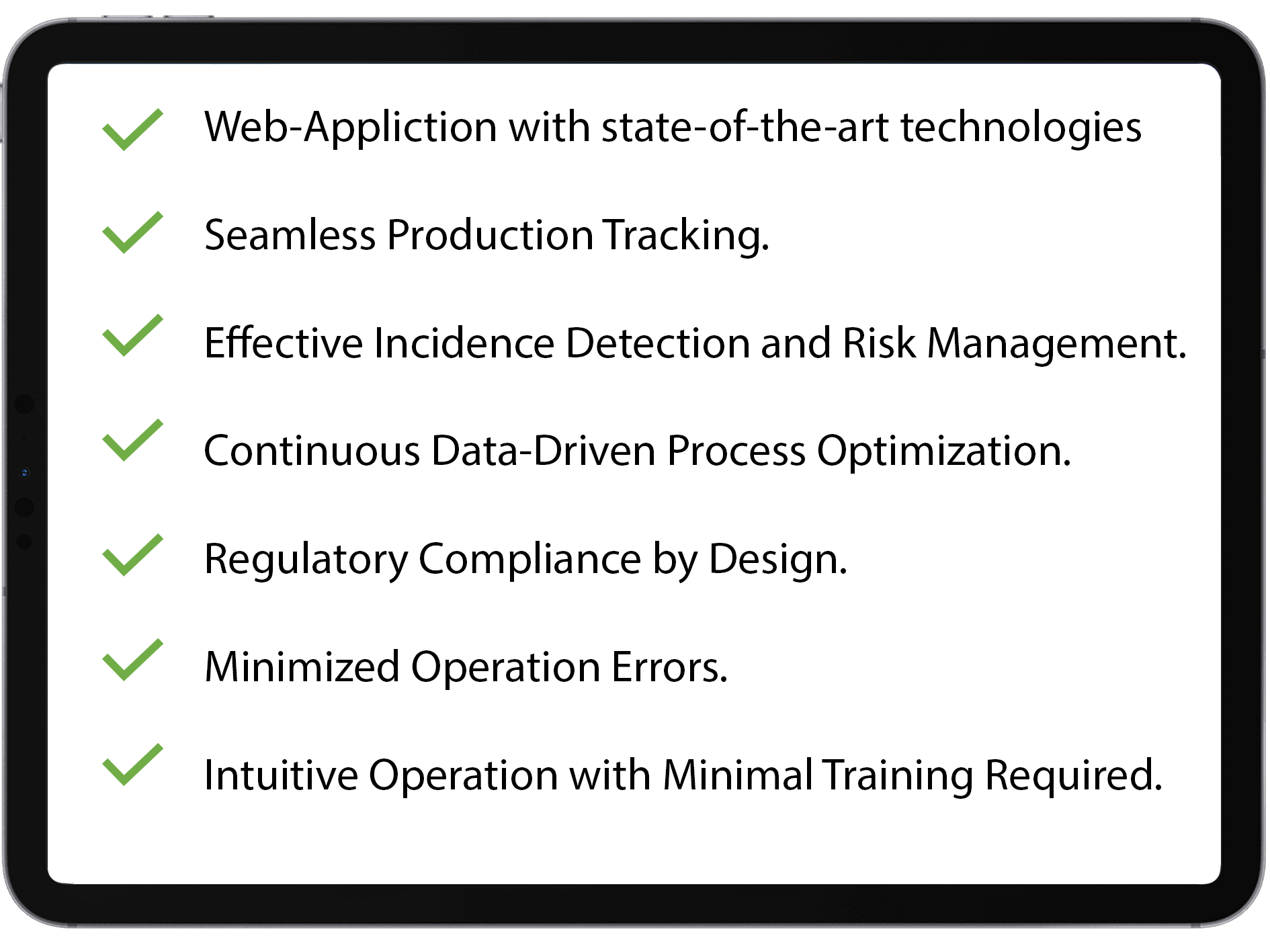

IT leverages state-of-the-art technology for seamless production tracking and robust data-driven process optimization. Designed with regulatory compliance and minimal operational errors in mind, it offers an intuitive interface requiring minimal training.

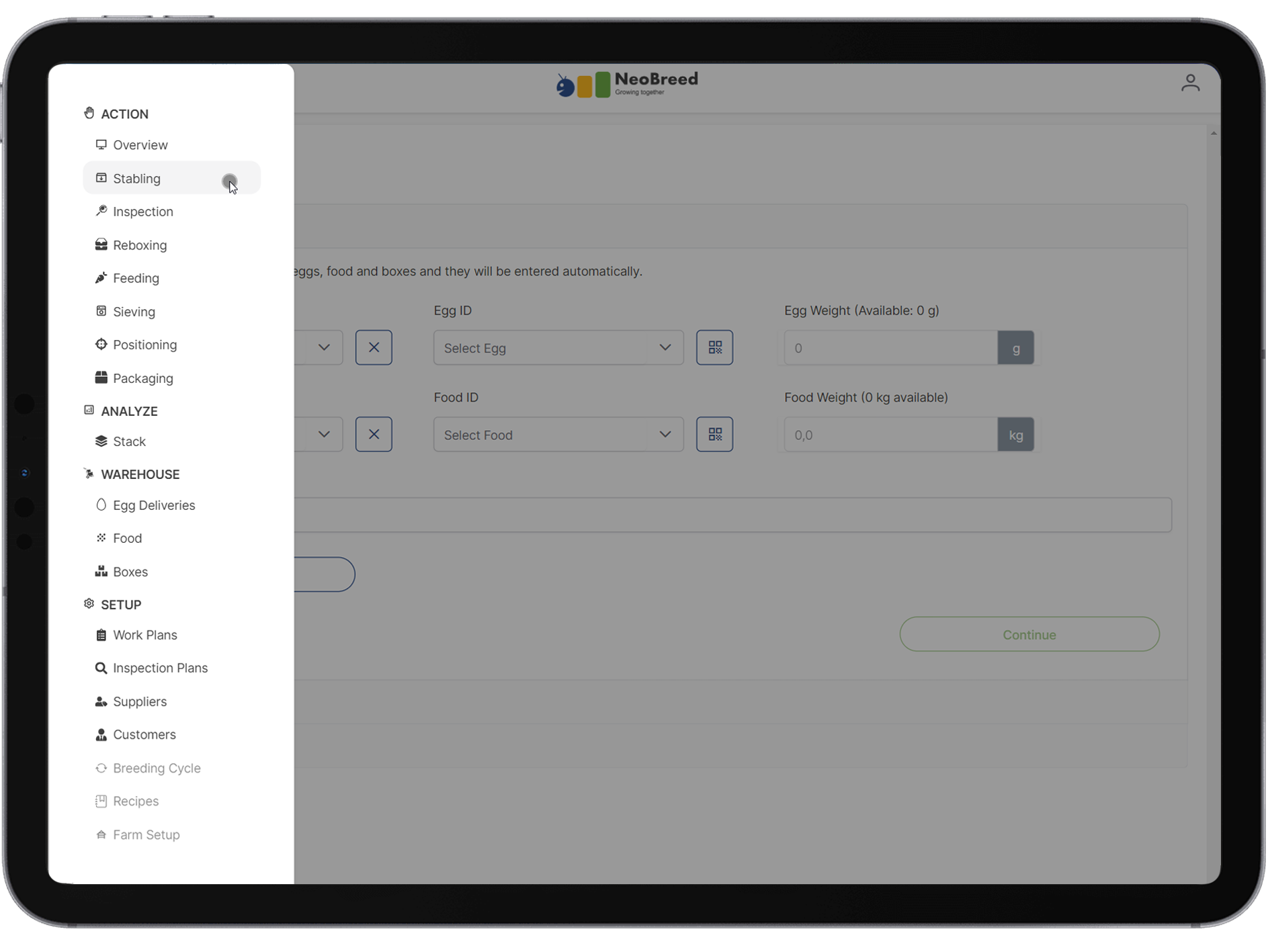

Plan and document your stabling process with precision. Specify key data including dates, egg types used, initial feed amounts, and associated work plans to seamlessly integrate into your production cycle.

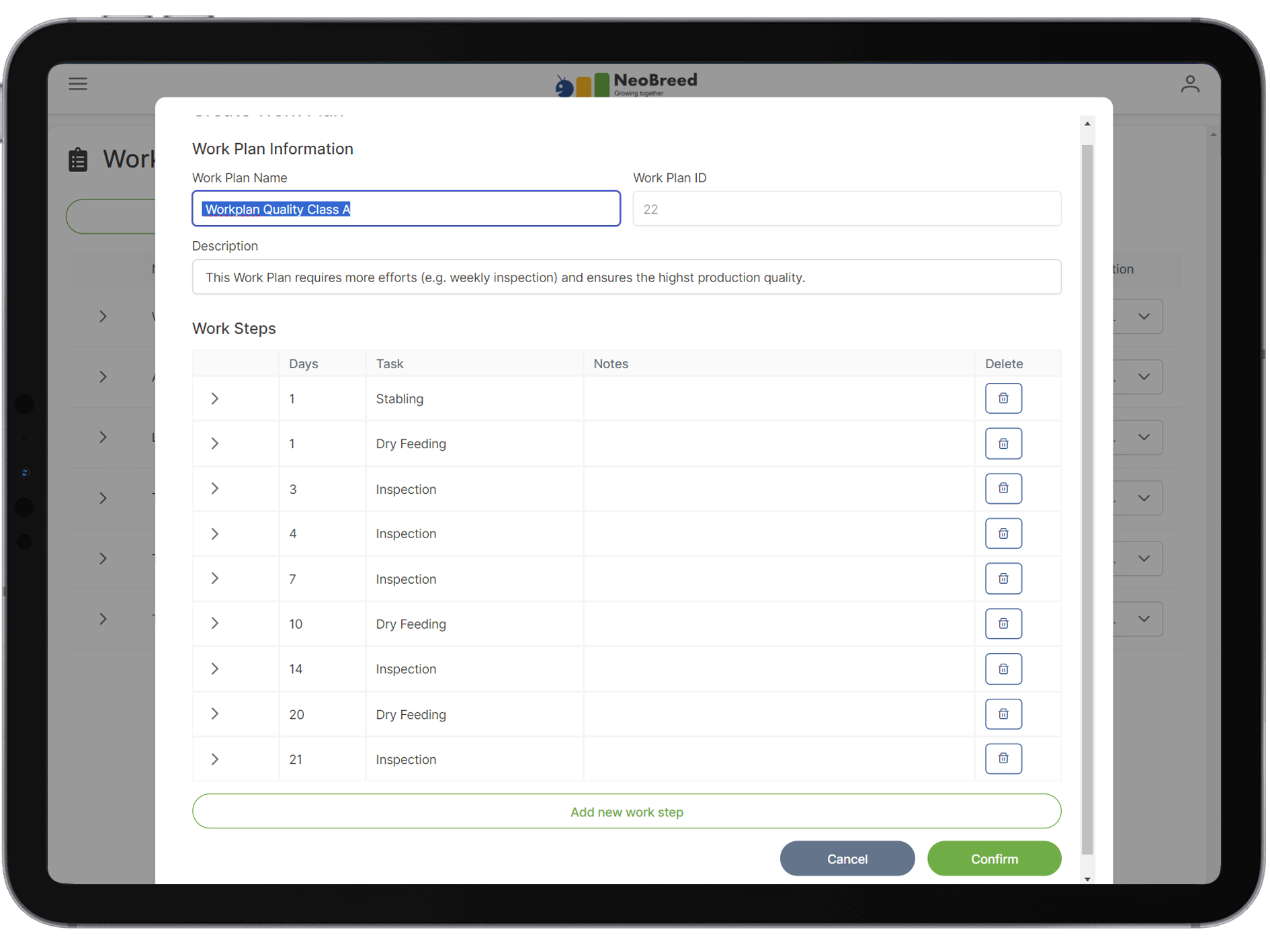

Effortlessly create and assign detailed work plans for each production batch tailored to specific production needs to ensure consistent quality and efficiency throughout the production cycle.

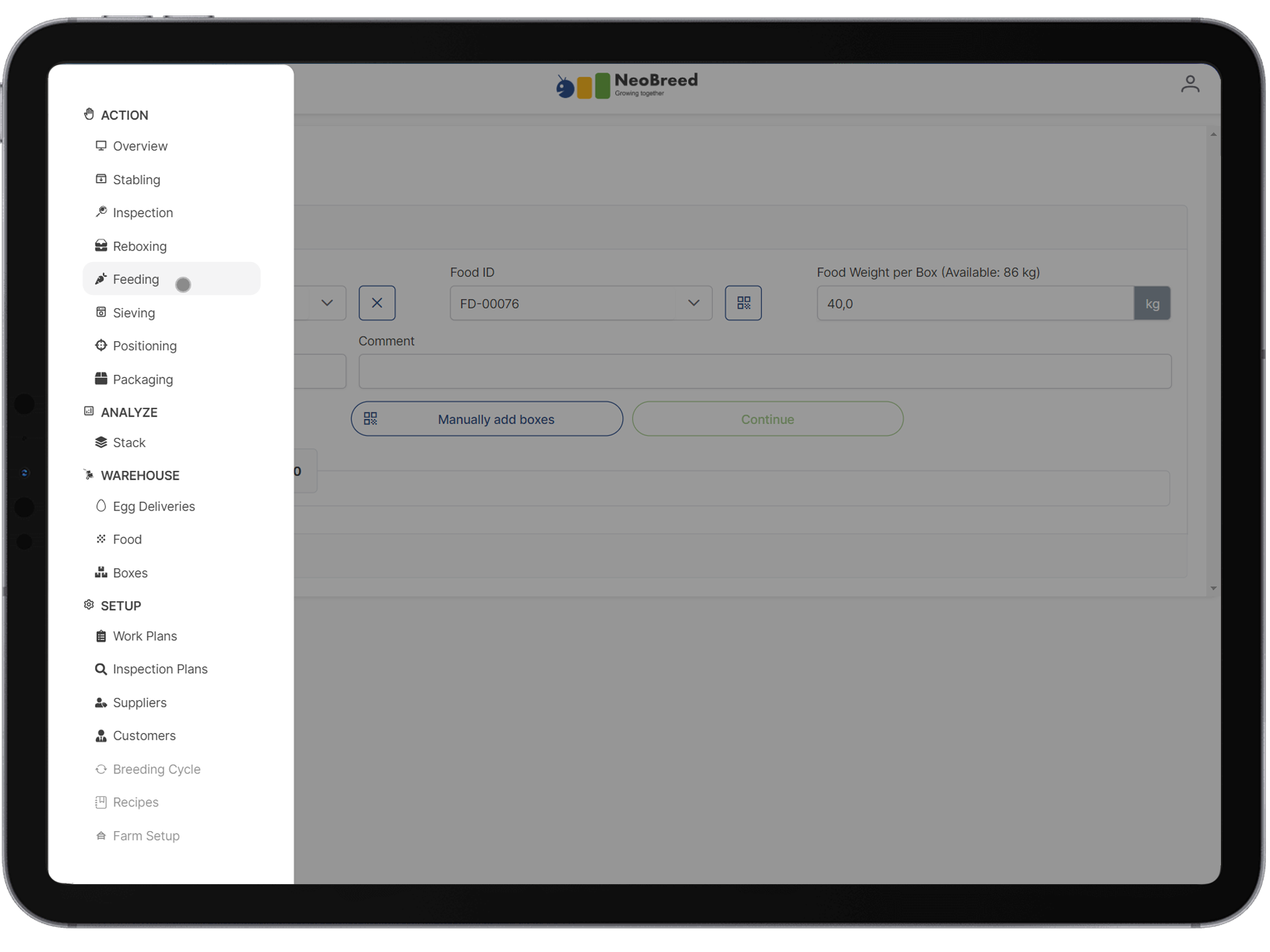

Maintain accurate feeding logs by documenting the food ID, amount used, and feeding dates. This meticulous record-keeping supports optimal nutrition and growth conditions throughout the lifecycle of the insects.

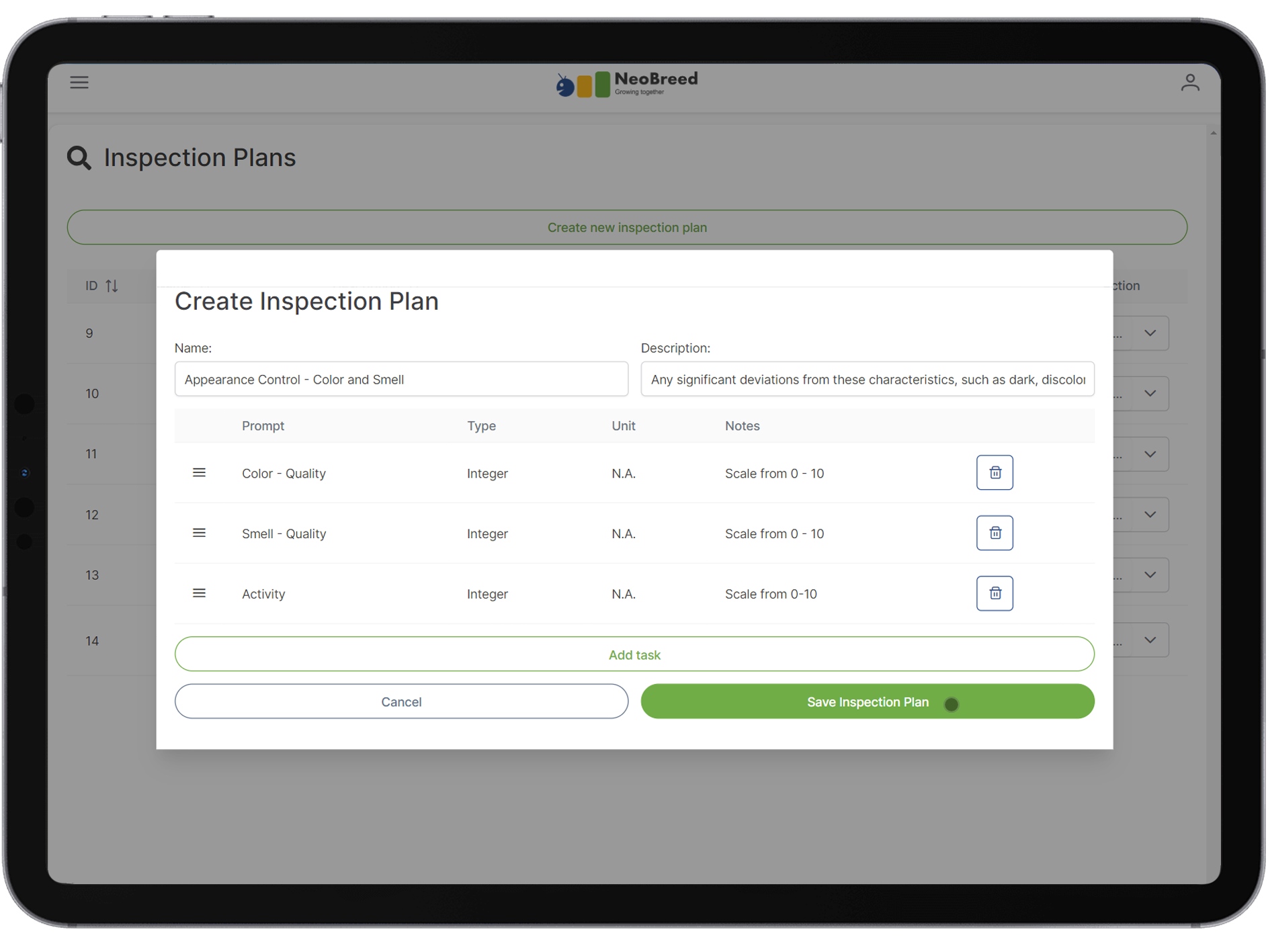

Tailor your inspection plans to meet specific needs by setting attributes, value formats, and units. This customization allows for precise and standardized inspections, ensuring consistent quality and compliance.

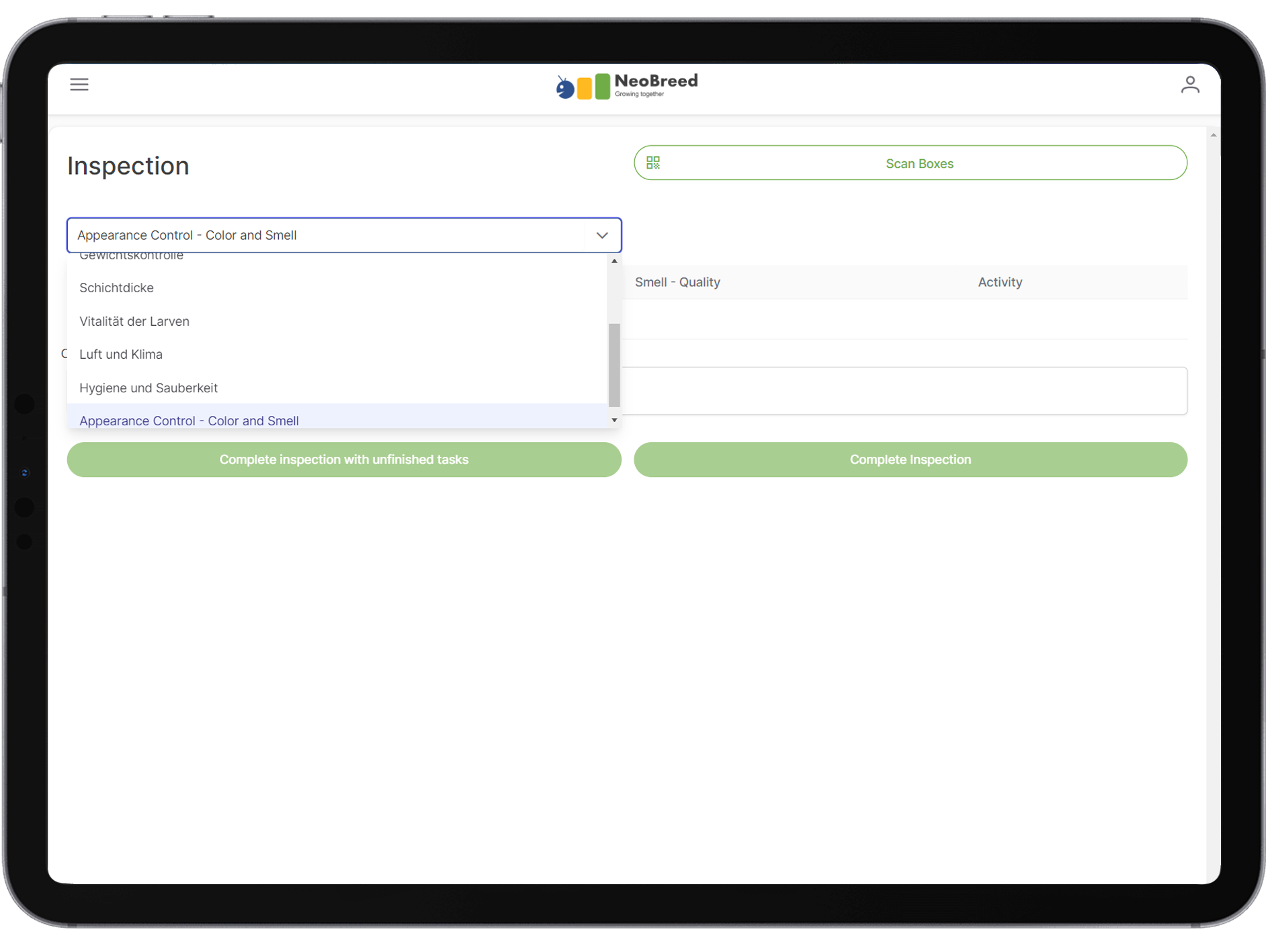

Execute and document inspections with precision, adhering to the customized plans. This ensures thorough monitoring and adherence to quality standards, essential for maintaining product integrity.

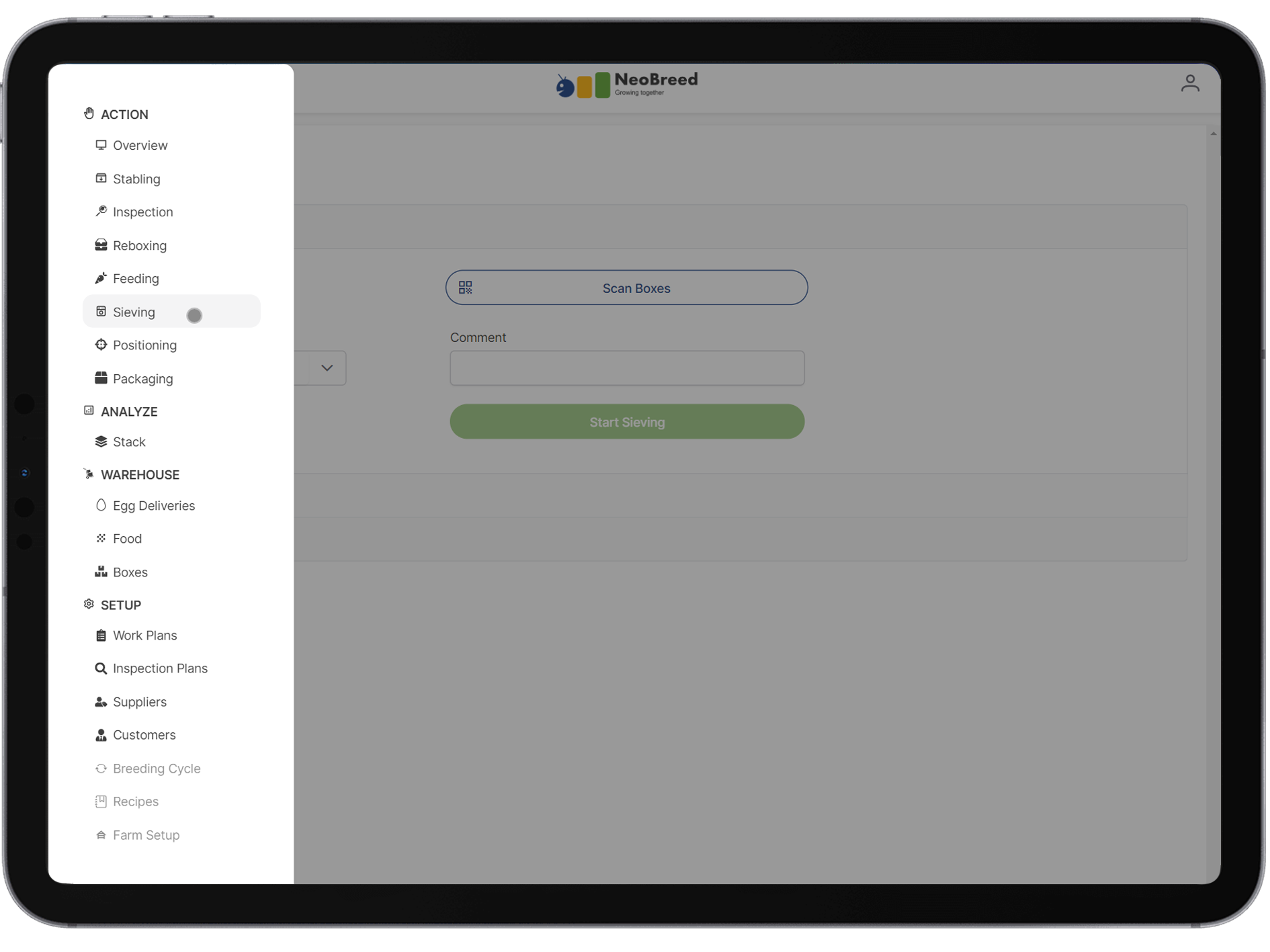

Record comprehensive data during the sieving process, including the weight of mature and immature insects, casualties, fecal matter, and residual food. This data is crucial for generating performance metrics and improving production efficiency.

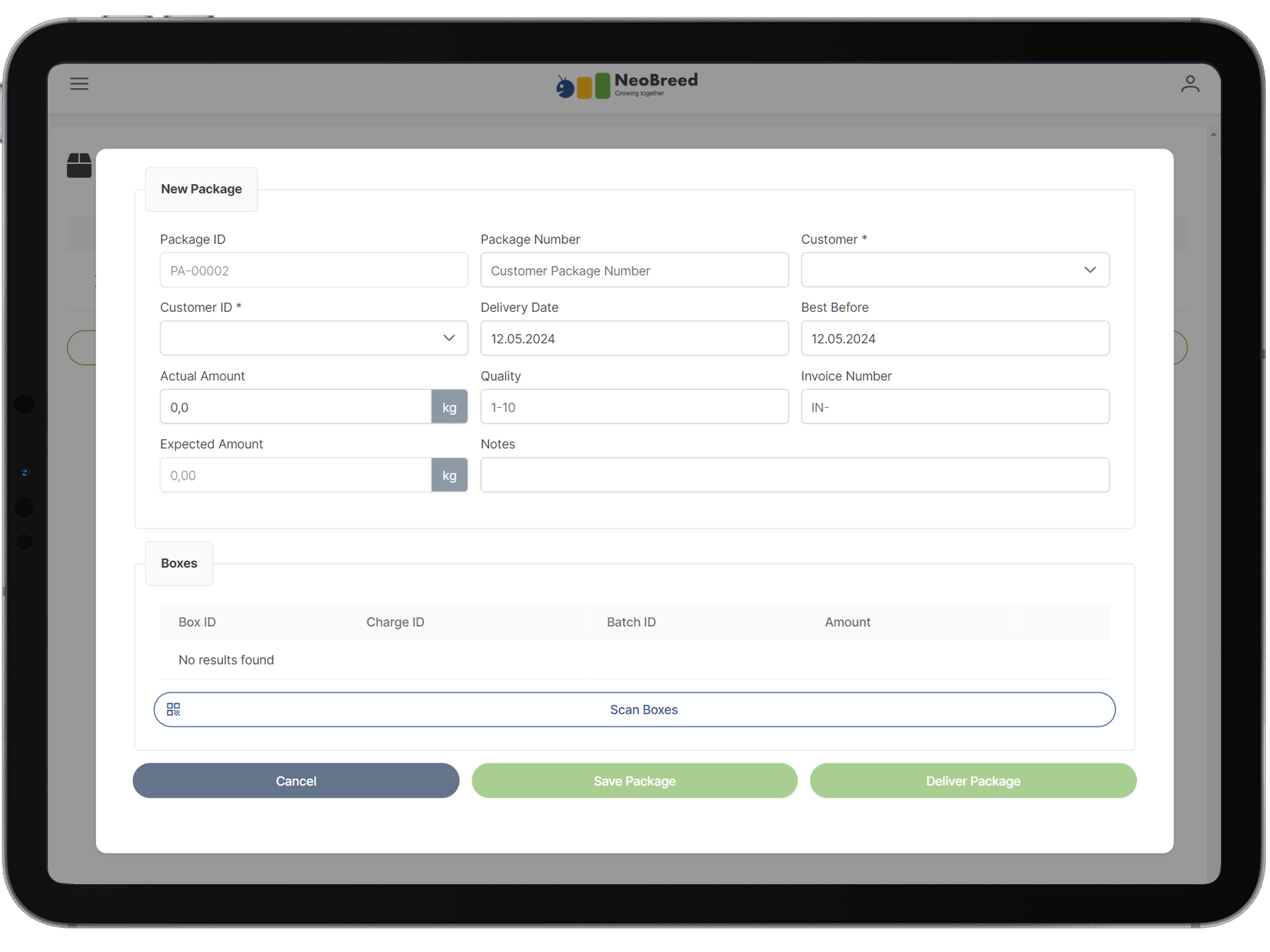

Conclude the production cycle by packaging sieved insects, preparing them for delivery. This final step ensures that the product reaches customers in optimal condition, maintaining the highest standards of quality and hygiene.

IT leverages state-of-the-art technology for seamless production tracking and robust data-driven process optimization. Designed with regulatory compliance and minimal operational errors in mind, it offers an intuitive interface requiring minimal training.

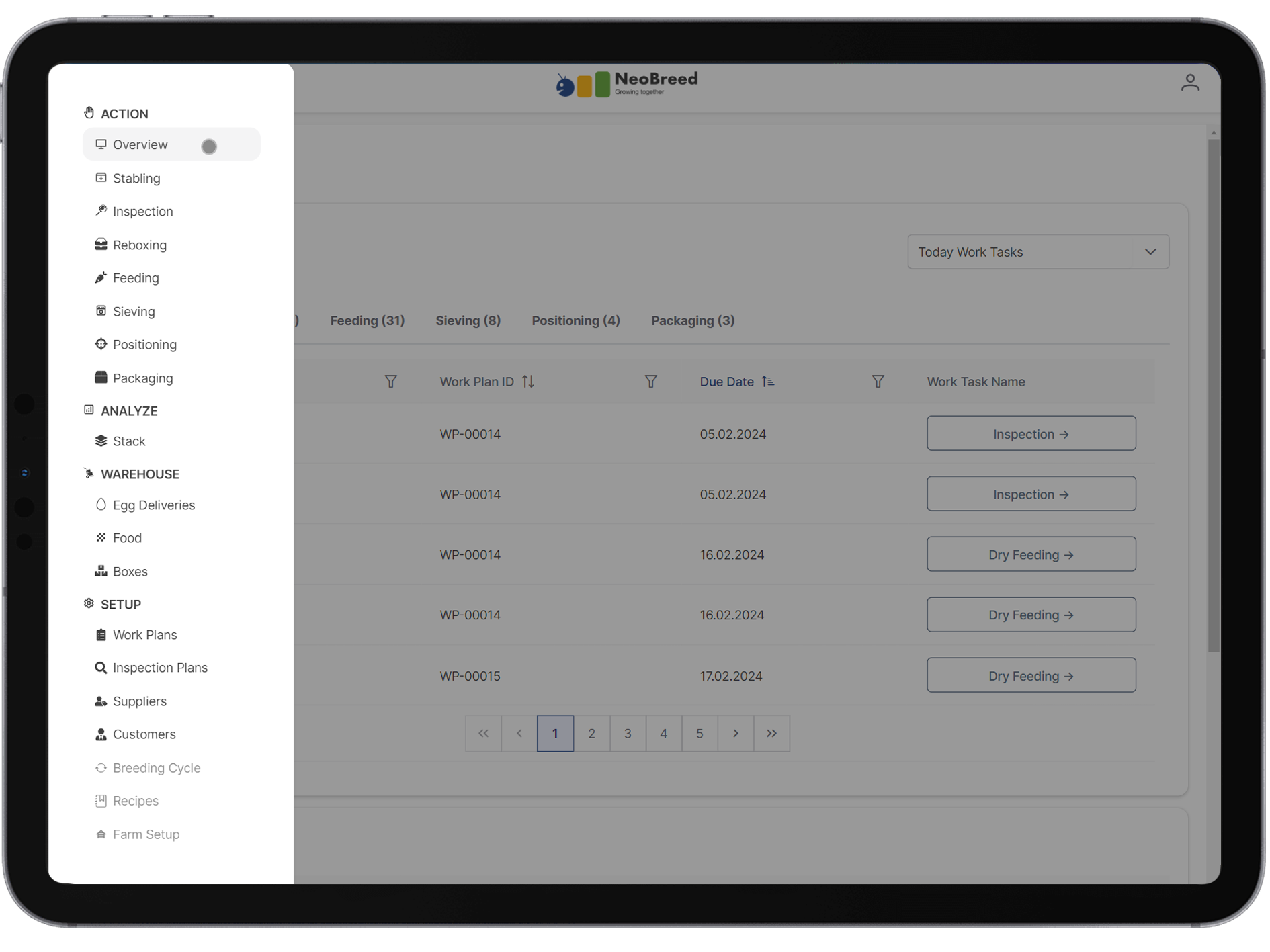

Seamlessly Plan and Track from Larvae to Logistics Planning of all work steps for a breeding cycle, scheduling and assigning tasks to operators, documenting work steps and related data throughout the breeding cycle.

Data-Driven Process Optimization and Quality Control KPI analysis (e.g., quality and efficiency) based on data from insect lifecycle, workflow, production conditions, and warehouse operations enables continuous optimization.

Control Signals to Automation Systems Automated systems receive direct task control signals, while an advanced computer vision module is being developed to capture key growth parameters during the breeding cycle.

Email us using our simple form and we'll respond within 10 working days.

gET A FREE TRIAL NOW!